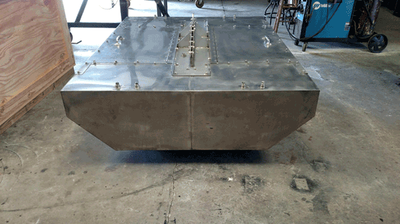

Floating SBR Decanter

|

|

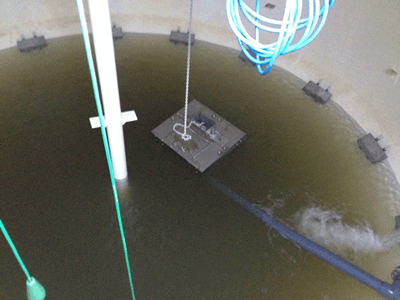

Solids Excluding Doors:

Keeps solids from entering the decanter head during the fill and aeration cycles. Automatically keeps scum out! Predictable Decanting Can Save Cycle Time. Sludge settling time, and decanting time can be combined to save total cycle time. Want an extra 10% production? Floating Decanter No need to determine the settled sludge level, since the decanter floats. It is not rotated into the fluid on a predetermined arc. Automatically bubba-proof! |

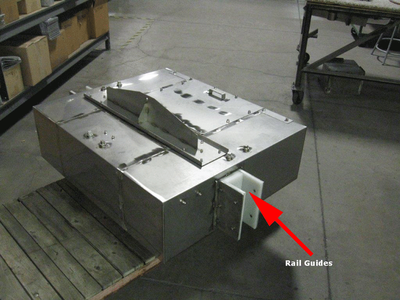

Fixed SBR Decanter

Fixed SBR Decanter

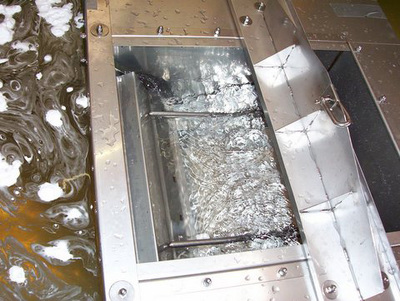

Uniform Withdrawal:

Selected units can maintain a consistent withdrawal rate of supernate over the entire range of decant. Across the width!

Solid simple systems. No maintenance! Bubba-proof!

Self Adjusting Weirs:

Create a definable flow rate, moving the super-critical acceleration into the decanter, leaving sub-critical flow outside of the decanter giving the highest possible flow rate without disruption of the sludge layer.

Decants automatically! Dependable hands-off operation!

Selected units can maintain a consistent withdrawal rate of supernate over the entire range of decant. Across the width!

Solid simple systems. No maintenance! Bubba-proof!

Self Adjusting Weirs:

Create a definable flow rate, moving the super-critical acceleration into the decanter, leaving sub-critical flow outside of the decanter giving the highest possible flow rate without disruption of the sludge layer.

Decants automatically! Dependable hands-off operation!

| Total Meters | Max Flow Rate* | Dimensions | Standard | |||

| Model No. | of Weir | m3/min | Gal/min | L x W x H | Weight | Port Size |

| SKIMOIL HD-00811 |

.5m | 1.4 | 370 | 34" x 60" x 20" | 160 lbs | 4" |

| SKIMOIL HD-02811 |

2m | 5.6 | 1,480 | 76" x 60" x 20" | 440 lbs | 8" |

| SKIMOIL HD-04811 |

4m | 11.2 | 2,958 | 140" x 60" x 20" | 640 lbs | 12" |

| Higher flow rates achieved with multiple heads. 304 Stainless Steel Construction, Sump and Lifting Bracket 12 gauge, Float and Weir 18 gauge. Flow Rate set to a desired rate of decanting normally 2.8 cubic meters per minute per meter of weir. ANSI Flange Bolt Pattern Standard * Flow Rate assumes at least a 18" head. |

||||||

| Dimensions and Specifics subject to change without notice. |

Floating SBR DecanterNo Electrical-Mechanical Devices Required.

This floating decanter self adjusts all variables to produce unloaded supernatant throughout the decant.

Single Point Control

Effluent control valve automatically controls adjustments and operations in the decanter head to the demands of the decant rate.

This floating decanter self adjusts all variables to produce unloaded supernatant throughout the decant.

Single Point Control

Effluent control valve automatically controls adjustments and operations in the decanter head to the demands of the decant rate.