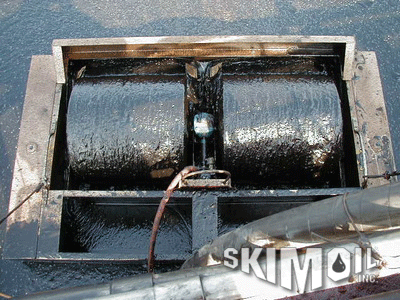

Oil Skimming for the Steel Mill IndustryOilyTip of the month: When skimming oil from the surface of the water—give consideration to where the oil is going and how it will be eventually separated from the water. If you use high shear pumps to move the oil—there WILL be SERIOUS headaches and problems ahead—due to the fact that you will create a mechanical emulsion—by chopping the oil into micro particles that are MUCH harder to separate from water. Some very small oil particles might not even float. Avoid when possible! These problems include the fact that they do get a lot of oil in the water, by accident as well as by design. A lot of the water handling and peripheral equipment leaks and/or drips oil, which winds up in the scale pits or in the wastewater treatment areas of the plant, which are often handled by central utilities departments, who don’t necessarily have the same agenda as the production people. Some production process, including some cold mills use an animal fat emulsion as a roll lubricant, which gives you a pretty nasty fragrant oily mess that has to be handled one way or another. Bottom Line here is that oil does get removed, BUT only when it absolutely has to be, due to quality issues or if there is enough heat from the environmental people to GET IT DONE! All it takes is one blown hydraulic line to put hundreds or even thousands of gallons of oil into the water system. Selective and Non-Selective Oil SkimmersIn the steel industry, oil skimming is done either selectively (oilonly) or non-selectively which gives you a lot of water to be dealt with. Selective oil skimmers always have some type of motor driven rotating element (mop, drum, belt, tube or disc) which attracts and collects oil which is then wiped, scraped or wrung off, usually gravity drained directly to or pumped away to storage. This selective oil skimming gives you relatively small amounts of water---which is actually mostly mixed in with the oil or the dirt that’s in the oil. Very little water in the oil is always a good thing---making recycle far easier and also making the oil more valuable because it requires less handling. Non-selective oil skimming is usually done by a floating weir type skimmer---which is essentially a floating low spot in the water that whatever is on the water’s surface flows into. The floating weir type oil skimmers are actually surface skimmers----in that they will also get scum, floc, fly-ash, or whatever is floating on the surface---near the skimmer. These floating weir skimmers work very well and have few if any moving parts BUT they give you a lot of water to deal with which is usually decanted from the collection tank---usually by people who don’t have the time to do it or stay on top of it. Handling the extra water is usually a problem unless you can put all the skim back into a system somewhere else. Get The Oily News with a simple honest email address. Want more...give more? Sign up here.

Comments are closed.

|